Thailand’s annual energy consumption has risen sharply during the past decade and will continue its upward trend in the years to come. While energy demand has risen sharply, domestic sources of supply are limited, thus forcing a significant reliance on imports. To face this increasing demand, Thailand needs to produce more energy from its own […]

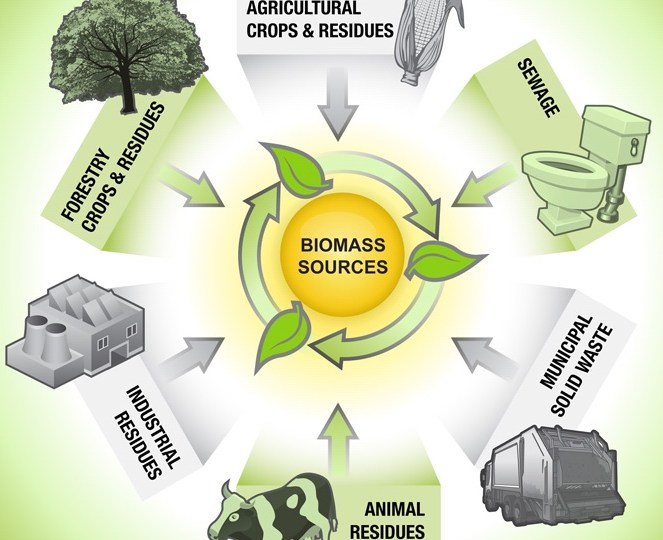

Biomass Energy in Thailand